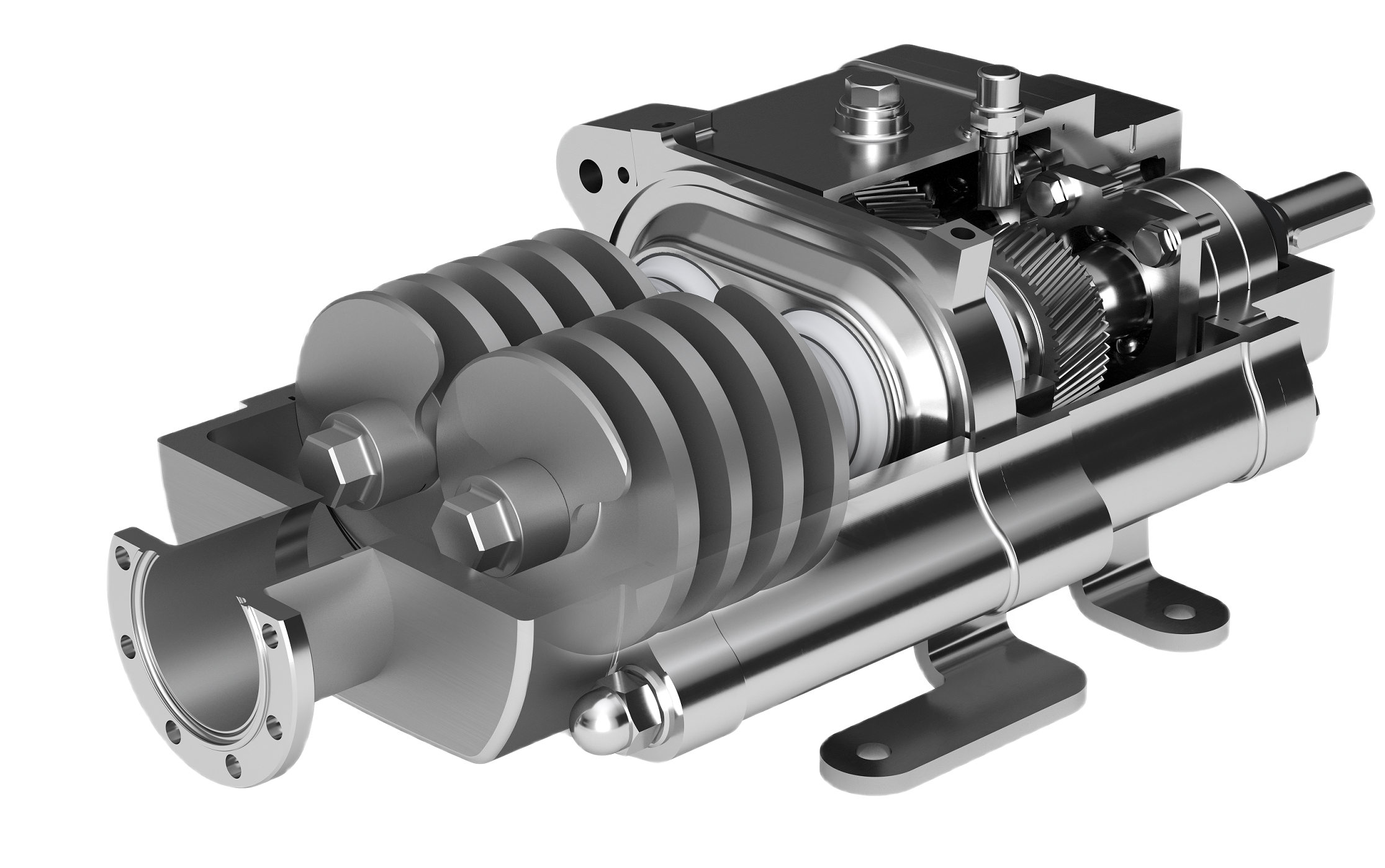

SLH twin-srew pumps

Would you like to test the SLH twin-screw pump?

Advantages of the SLH twin-screw pump

The 2-in-1 principle

Thanks to the wide range of speed values of the SLH pump, up to 3600 RPM, it is possible to perform a process cycle as well as CIP and SIP using the same pump.